Our know-how

Explore our collection of tide clocks, where each model captures the timeless elegance and precision of the tides.

The taste for things well done

At Ocean Clock, we believe in the beauty of durable objects that are useful, simple, and beautiful.

Behind each creation, there are ideas, gestures, carefully chosen materials, and a dedicated team that oversees each stage of production.

It is this know-how that we cultivate day after day in our workshop in Soorts-Hossegor, in the heart of the Landes, where our brand was born.

We are not a large industrial group. We are a manufacturer, an independent designer, proud to design and manufacture our products with respect for the materials, techniques, and values that have driven us since the beginning.

A manufacturing process like no other

It all starts with an idea. Then come the sketches, the prototypes, and the adjustments. Our manufacturing process is driven by the desire to master each step as much as possible, to guarantee quality products, designed to last.

Our tide clocks, like our measuring instruments (barometers, thermometers, and lunar clocks), are manufactured using a short supply chain and sustainable manufacturing process. A large portion of the parts are produced in France, sometimes even in our own workshop.

Wood, the central material

We work primarily with wood from forests located in France, Germany, and Eastern Europe. The wood we use is certified and selected for its quality and stability.

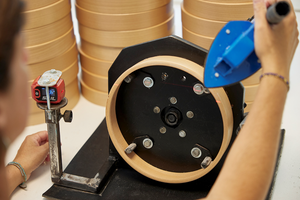

Some of the wooden parts, particularly those on which we affix our dials, are cut in-house using our CNC machine. This allows us to have even greater control over the precision and quality of our production.

Each piece of wood is then sanded, sometimes by hand, and prepared to receive the graphic or technical elements that will make it a unique object.

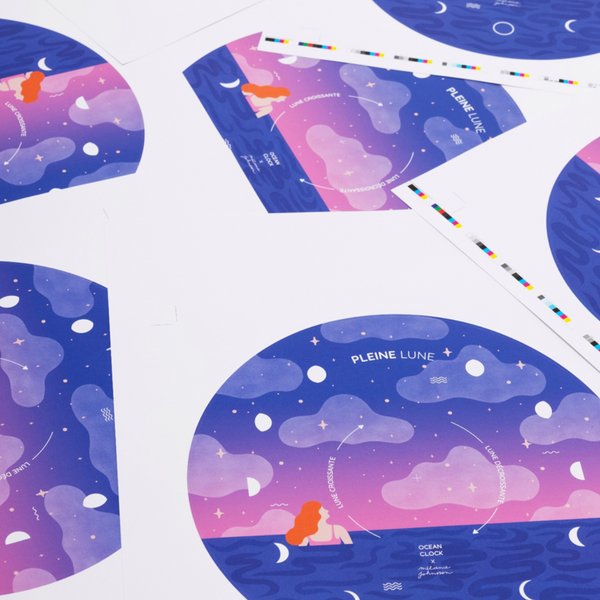

Locally printed, durable and neat dials

Our dials are printed in a company located near Bordeaux, on an impressive machine over 15 meters long.

This technology allows us to print with exceptional precision and use pantones specific to our brand, for faithful and consistent colors.

Each dial is treated to resist UV rays, and we have chosen not to use petroleum-based plastic coating, for a finish that is both aesthetically pleasing and more environmentally friendly.

Technical pieces with invisible details

Some parts are invisible to the naked eye, yet essential to the quality of our products. Our spacers, for example, are manufactured in the Landes region by a specialist in technical materials. They appear perfectly round, but are actually slightly concave, ensuring perfect stability.

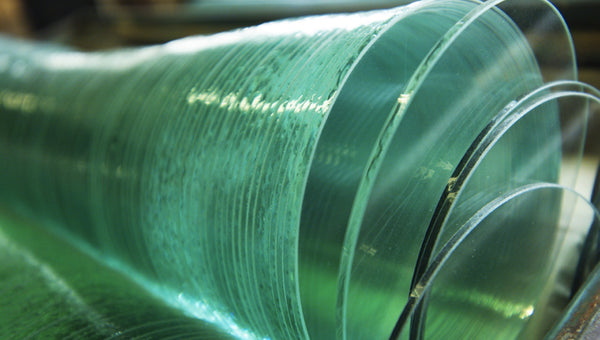

Our thermometer holders are made in France, near Rennes, before being sanded and prepared in our workshop. As for the glass that protects our dials, it comes from a German company specializing in watchmaking since 1888 a guarantee of precision and expertise.

Trusted partners

We use family businesses and French artisans for many specific pieces.

The custom adhesives used in assembly are manufactured in the Vosges region by a family business with expertise in this field.

Our packaging is designed in the Gers region by a company specializing in custom packaging, particularly for Armagnac.

These packages are designed to effectively protect our products while avoiding unnecessary over-packaging.

Innovative materials, designed for tomorrow

Some parts, such as the second hands of lunar clocks, are made from PLA, a bio-sourced material made from corn starch.

This choice is part of our desire to develop ever more responsible products, without compromising aesthetics or precision.

Manual gestures, at the heart of our workshop

Over the years, our workshop has become a true place of creation.

Each product passes through several hands. Some parts are hand-painted, like our barometers, where Morgane applies her time to each piece to ensure a flawless finish.

Customizations are also carried out on site, thanks to our engraving machine, to offer unique products, designed for each customer.

All assembly is carried out by our team members in our workshop. This is precise, meticulous work that requires experience and concentration.

A balance between local know-how and openness to the world

Even if we choose to go local whenever possible, some parts cannot be produced in France.

This is the case, for example, of the mechanisms manufactured by a Chinese company specializing in watchmaking and measuring instruments for over 25 years.

This company is ISO 9001 certified, particularly for its human resources management.

We chose this supplier for the consistent quality of its movements and the transparency of its practices.

A passionate team behind each creation

At Ocean Clock, we are a close-knit team, driven by the same passion for a job well done.

We share tasks, ideas, and finishing touches. We test, correct, and refine.

And above all, we manufacture each product with the desire to offer a useful, poetic, durable object.

From the idea to the ready-to-ship package, everything is designed here, in our workshop in Hossegor, in the heart of the Landes region, France.

A brand

A committed and recognized brand

Ocean Clock is now a recognized brand, distributed in more than 250 points of sale.

Our tide clocks have become a symbol of our expertise, but also of our vision: that of a decorative object that has meaning, that tells a story.

In 2025, Ocean Clock officially obtained the Made in France label, an important milestone that recognizes our commitment from the beginning.

Even if not all the parts are yet French, a large part of our manufacturing is now carried out locally, in-house or with trusted partners.

Know-how that continues to evolve

which continues to evolve

We don't claim to have mastered everything. But we're learning, we're testing, and we're always looking to do better.

Our know-how evolves with time, tools, and materials.

We remain true to our values: creating useful and durable objects, without ever losing sight of the essential, simplicity, sincerity and care.

AT THE HEART OF THE WORKSHOP, SKILLED AND PASSIONATE HANDS

The crew

FLORINE

Since 2018, Florine has been overseeing the workshop’s organization. With us almost from the beginning, she coordinates production with great rigor and dedication. She manages schedules, ensures the quality of parts, and oversees the smooth handling of orders. Her precision is invaluable in a place where every move counts.

CLAIRE

By her side, Claire is the expert in gluing, assembling mechanisms, fitting hands, and finishing thermometers. She knows every step by heart and adjusts each piece with millimeter accuracy, showing impressive consistency.

AURÉLIE

She is our specialist for barometers and moon phase clocks. Aurélie assembles these delicate instruments with method and precision, where every component matters to guarantee optimal performance all without ever compromising on aesthetics.

MORGANE

Finally, Morgane is the queen of meticulous tasks. She handles elements that require patience, precision, and a keen eye. Fine painting and finishing details nothing escapes her attention.

Each of them brings their own touch, their expertise, and their attention to detail. Their dedication makes the difference and gives each object a soul. Ocean Clock would not be what it is without this committed, passionate workshop team, proud to see their creations join your interiors.

Sharing experiences:

Our workshop

In our watchmaking workshop, each cog plays a role...